Our three membrane constant pressure gasholder domes are installed on newly constructed or pre-existing digester tank and designed to recover and collect biogas directly from the tanks. TheCUPOLA M3 is an ideal choice for replacing an existing steel gasholder dome and offers an opportunity for storage volumes to either be maintained or increased, while reducing replacement and maintenance costs. Installation is quick and takes approximately one week to complete.

The CUPOLA M3 is constructed using PVC-coated fiber fabrics (UV-microbial-abrasion-biogas resistant) and welded together using high frequency welding (ISO 9001 quality). All welding edges are sealed using an Eco-Safe layer of pure PVC in order to prevent biogas and other contaminants from degrading the fibers within the membrane.

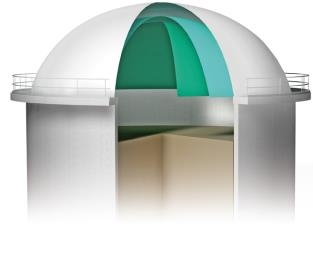

Greater Level of Operational Safety. The CUPOLA M3 system incorporates two completely separate chambers for the air and the biogas, thus preventing the possibility of gas leakage into the controlled air volume. Rather, any gas that might leak from the biogas chamber flows naturally through the free space between the biogas chamber and the intermediate membrane, avoiding a potentially dangerous mix of biogas and air stored in the air chamber. In the event of a power failure, the CUPOLA M3 system uses the air valves to lock in the biogas, maintaining the structural integrity of the gas holder long enough for a temporary generator to connected, power to be restored, and if necessary, biogas to be flared.

Accurate Pressure Control. The CUPOLA M3system allows pressure to be maintained while biogas is filling the gasholder, and only requires blower operation when biogas is being used. The working pressure of the CUPOLA M3 is controlled mechanically using adjustable air relief valves mounted on the side of the air membrane.

Power Savings. With the CUPOLA M3 system, the use of an air blower is only required during the initial filling of the membrane, for compensation and for maintenance of a constant pressure when biogas is being drawn out. This provides power savings compared to the CUPOLA M2system, which requires a continuously operating blower.

Level Control System. A patented electro-mechanical system accurately records the level of the internal biogas membrane’s apex, so that operators can accurately gauge the volume of biogas stored in the gasholder. This avoids the usual difficulties encountered with ultrasonic level detection such as false volume readings due to target misalignment.